In-Space Manufacturing with CubeSats

The MakerSat-1 was the first CubeSat assembled and deployed while in space. Printed in the Made In Space Additive Manufacturing Facility, these support structures snapped together to create a 1U CubeSat frame. Credit. Made In Space.

Two new in-space manufacturing research missions were recently deployed into low Earth orbit. The missions, MakerSat-1 and Orbital Factory 2, are each housed in 1U CubeSats (10x10x10cm). MakerSat-1 is studying the degradation of common 3D printer plastics in space, and Orbital Factory 2 is demonstrating 3D printing of conductive material, simulating a solder joint repair on a solar array while in microgravity.

MakerSat-1 is novel because it is the first satellite assembled and deployed while in space. Designed by Northwest Nazarene University (NNU), the structural components were 3D printed aboard the International Space Station (ISS). Assembly only required snapping the components together; NNU claimed an astronaut could accomplish the task within 5 minutes. This assembly process is clever because most CubeSats have a tedious assembly requiring dozens of small fasteners that are secured in a specific order. The satellite electronics were pre-assembled PCBs shipped up from Earth. Assembly only required plugging in wires and slotting the PCBs into the 3D printed structure.

The Made In Space Additive Manufacturing Facility (AMF) was used to actually print the structural components of MakerSat-1. AMF is a commercially available fused deposition modeling (FDM) printer, the main type of 3D printer used for plastics. AMF has been aboard the ISS since 2016. The AMF is able to print common plastic types within its 14x10x10cm build volume. This build volume is small for FDM printer standards, but is still sufficient for well designed components.

Aside from demonstrating an in-space assembly of a CubeSat, MakerSat-1’s mission is to study how the harsh environment of space impacts the 3D printed plastic structure throughout its lifespan. This continues the research of MakerSat-0, which also studied the degradation of plastic polymers in space. MakerSat-0 used a similar 3D printed plastic structure, although it was launched from Earth already fully assembled.

While also a 1U CubeSat studying in-space manufacturing, Orbital Factory 2 (OFII) is a very different mission than MakerSat-1. Built by The University of Texas at El Paso, OFII is testing a mechanism that can place highly conductive ink on a PCB, simulating the process required to repair a solar array.

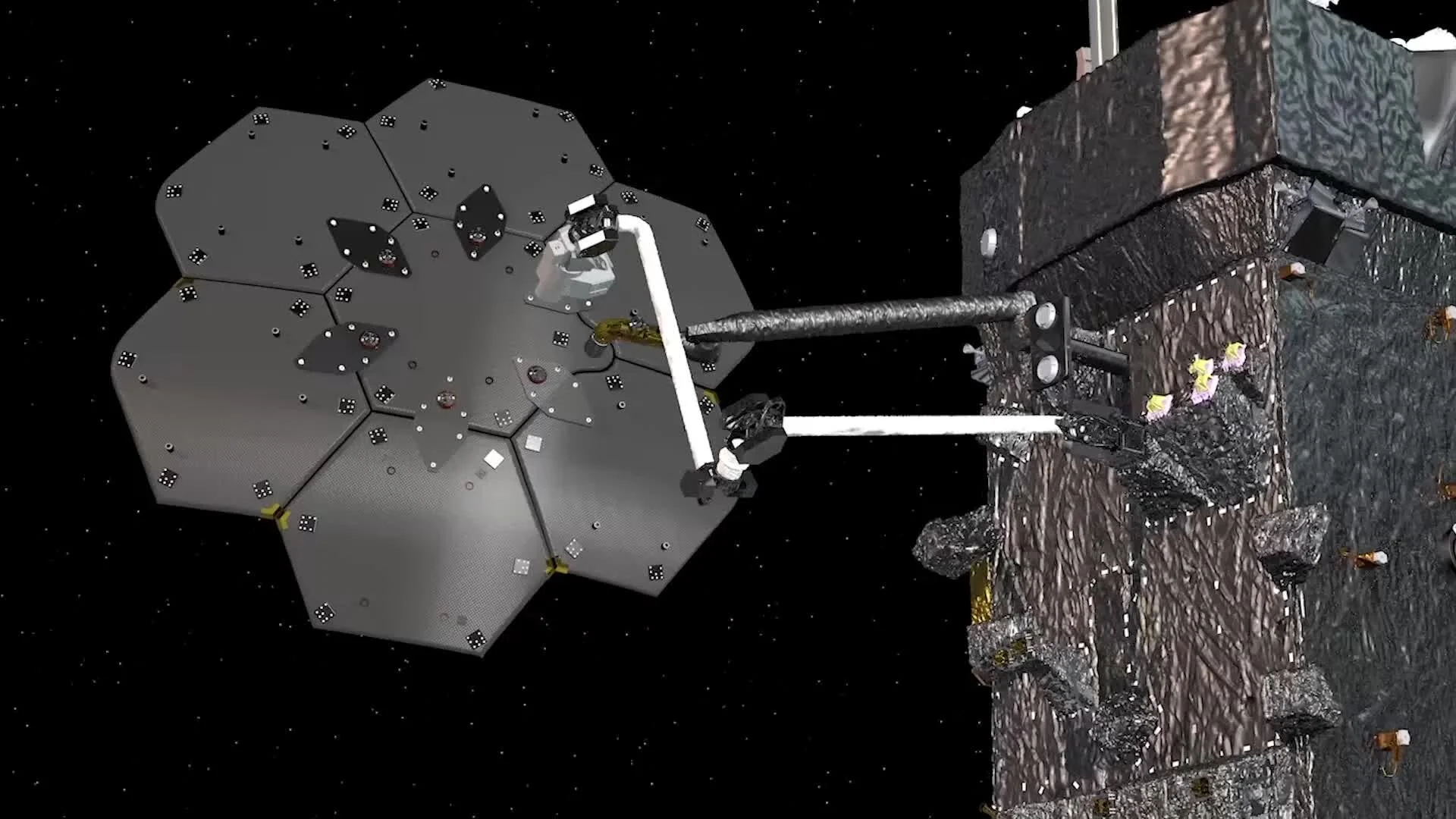

The print bed on the one-axis Orbital Factory 2 CubeSat. The extrusion structure (cylindrical object) extrudes a conductive ink (silver material) along the side of the PCB (green board). The conductive ink was selected due to its favorable properties in the space environment. This procedure simulates a solar array repair. Credit: Quintana et al., 2019.

Interestingly, OFII also included 3D printed structural components, albeit printed in an Stereolithography (SLA) printer, also known as a resin printer. The structure used for the demonstration is a single-axis 3D printer mechanism (side to side movement) that is embedded within a 1U CubeSat chassis. This table allows the conductive ink to be deposited in a line on a PCB. Ultimately, this will be an early test for using 3D printer technology in the open vacuum of space while exposed to microgravity and extreme temperatures.

3D printing in space is challenging because the environmental conditions are much more extreme than on Earth. Regardless of material, 3D printing requires a rigid printing structure and specific temperature range of the extrusion head and print surface. Rigid structures are bulky and heavy, which becomes a challenge when spacecraft are size and mass limited. Additionally, temperature controlled spacecraft environments are complex, expensive, and heavy. Finding effective approaches where 3D printers can be used in space will reduce the unnecessary mass and costs in these systems, allowing them to take advantage of the microgravity environment for building structures that do not need support material.

Both CubeSat missions have been deployed by the Cygnus cargo craft after it departed the ISS last week, and appear to both be operational. The core tests will occur over the next few months. Although these missions are only incremental technology demonstrations for in-space manufacturing, proving terrestrial methodologies in space advances the technology readiness for these concepts, allowing more ambitious missions in the future.